What are spot colours?

Spot colours (also known as solid colours) are specific pre-mixed inks that are printed using a dedicated printing plate on a printing press. Unlike process colours (CMYK), which create different shades by combining cyan, magenta, yellow, and black inks in varying percentages, each spot colour is a single, pure ink that produces consistent and precise results.

Spot colours are essential for specialty printing requirements that go beyond standard CMYK capabilities. They can indicate special printing techniques, finishing effects, or production processes like cutting, folding, or drilling. They allow designers to communicate specific instructions to printers and fabricators without ambiguity.

Why use spot colours?

Spot colours offer several advantages for specific applications:

- Precise colour matching: Spot colours deliver consistent colour reproduction that cannot be achieved with process colours, especially for brand colours, metallics, or fluorescents.

- Special finishing instructions: Spot colours can communicate precise production requirements to printers, such as where to cut, fold, engrave, or drill material.

- Production efficiency: Using defined spot colours helps streamline the production workflow by clearly indicating special treatments in your design files.

- Material compatibility: Some spot colours are designed specifically for certain materials and production methods, ensuring optimal results.

For large format projects specifically, the larger dimensions make proper bleed even more critical as even minor alignment issues become much more noticeable on a banner or poster than they might on a business card. Taking the time to set up your bleed correctly saves both time and money by preventing the need for revisions and reprints.

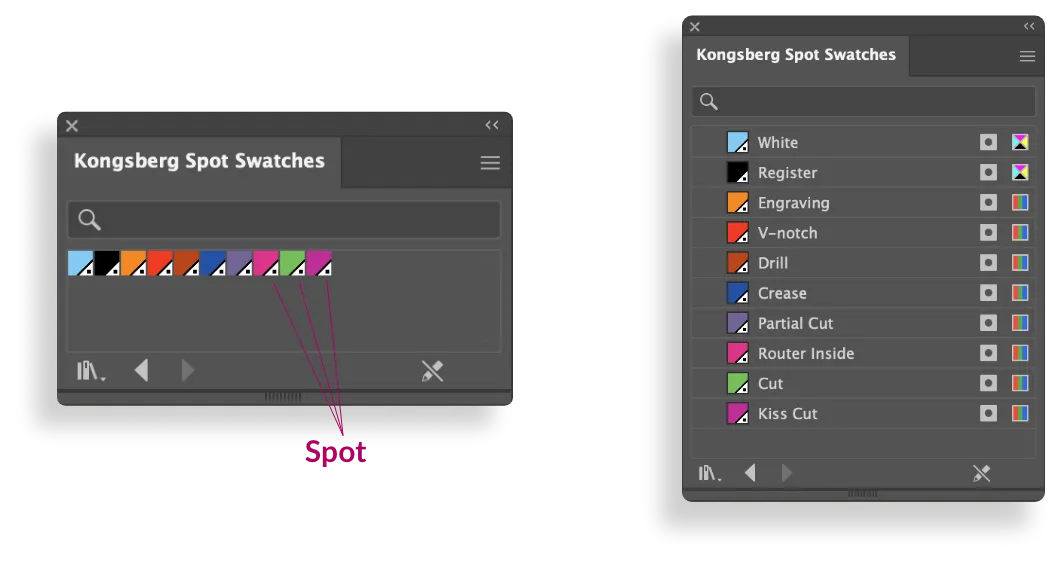

Our available spot colours and their applications

Printing colours

• White: Used for spot or flood white printing on coloured or transparent materials. White ink is often needed as an underbase for printing on dark materials or for creating opaque areas on transparent substrates.

• Register Black: Used for registration dots and marks that help align multiple printing plates. These marks are typically trimmed off in the finishing process.

Cutting and finishing colours

• Cut: Indicates lines for blade or mill cutting all the way through the material. The machine will cut exactly on this path, completely separating pieces of the material.

• Kiss Cut: Used primarily for vinyl lettering and stickers where the cut goes through the top layer but not the backing material. This allows for easy peeling of individual elements.

• Partial Cut: Indicates areas for milling to specific depths, creating recessed areas without cutting completely through the material.

• Engraving: Designates areas where the material should be engraved, creating shallow, detailed impressions.

• Router Inside: Specifies routing that occurs on the inside of a path. This is crucial for interior cutouts like the inside of letters (such as O, A, or P), ensuring that the cutting occurs on the interior edge of the path rather than the exterior.

• Drill: Marks points where holes should be drilled through the material.

Cutting and finishing colours

• Crease: Indicates where packaging materials should be scored for clean folding without breaking.

• V-Notch: Designates a 45-degree angled cut used for packaging and point-of-sale displays, allowing for precise folding after cutting.

How to install spot colours?

By following these guidelines, you’ll be able to effectively communicate your design and production requirements using our spot colour system, ensuring your projects are produced exactly as intended.

Installing our spot colour swatches in Adobe Illustrator

Our spot colour swatches are available in an Adobe Swatch Exchange (.ase) file format, which can be easily imported into Illustrator. Follow these steps to install them:

- Download the swatch file: Download our spot colour swatches from

[LINK TO BE ADDED BY CLIENT]. - Open Adobe Illustrator: Launch Illustrator with any document.

- Open the Swatches panel: If the Swatches panel isn’t visible,

go to Window > Swatches to display it. - Access the Swatches panel menu: Click on the small menu icon (☰) in the upper-right corner

of the Swatches panel. - Import the swatches: Select “Open Swatch Library” > “Other Library…”

from the dropdown menu. - Navigate to the downloaded file: In the file browser that appears, locate and select

the downloaded .ase file. - Verify installation: The spot colours will appear in a new panel. To add them to your current

document’s Swatches panel, simply click on each swatch you want to use.

Using spot colours in your designs

Now that you’ve installed our spot colour swatches, here’s how to effectively use them in your designs:

Creating new elements with spot colours

- Select the spot colour from the Swatches panel.

- Create your shape or path using any of Illustrator’s drawing tools.

- Apply the spot colour by ensuring it’s selected as the fill or stroke colour.

Converting existing elements to spot colours

- Select the element you want to modify.

- Open the Swatches panel and select the appropriate spot colour.

- Apply the spot colour to either the fill or stroke of the selected element.

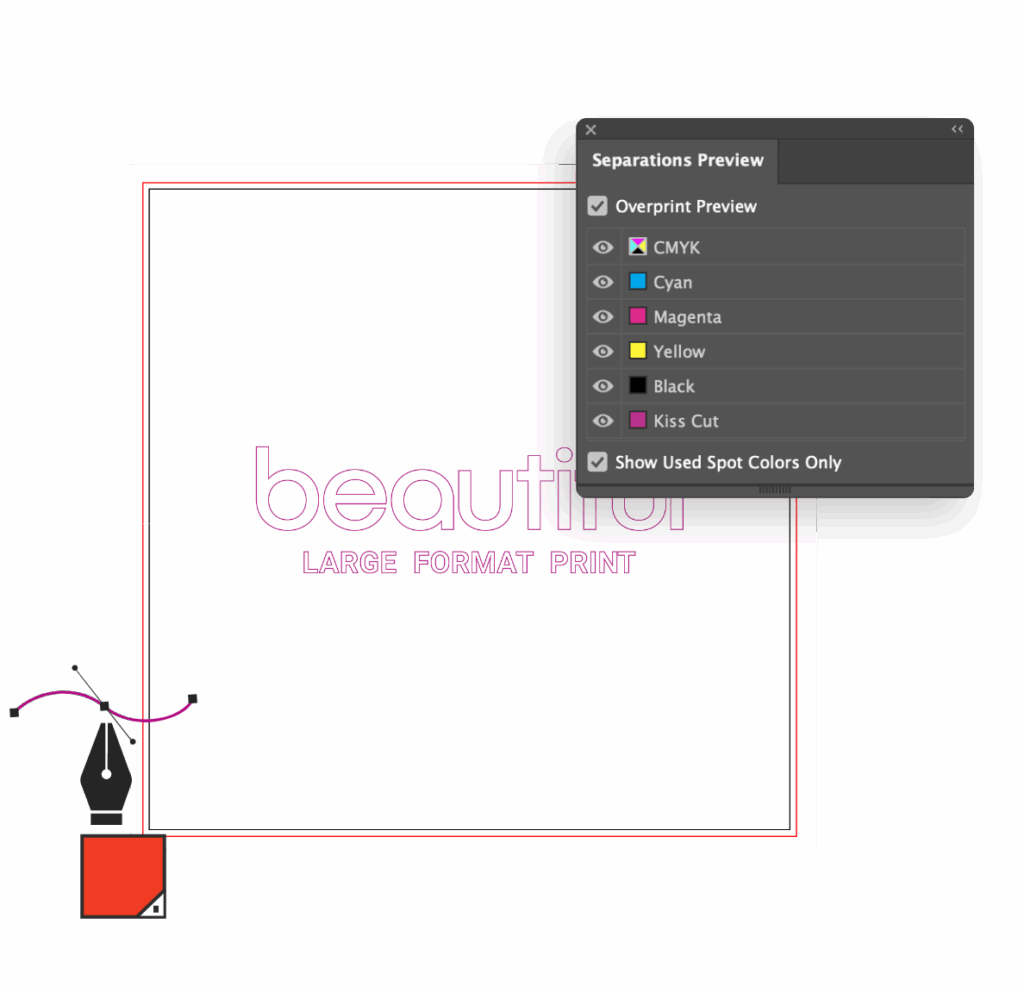

Checking for correct spot colour usage

- Open the Separations Preview panel by going to Window > Output > Separations Preview.

- Enable separations view by checking “Separations” in the panel’s View dropdown.

- Verify spot colours by toggling individual colour plates on and off using the eye icons next

to each colour name.

Best practices for using spot colours

Setting up cutting lines

For elements that require cutting (using the Cut, Kiss Cut, or Router Inside spot colours):

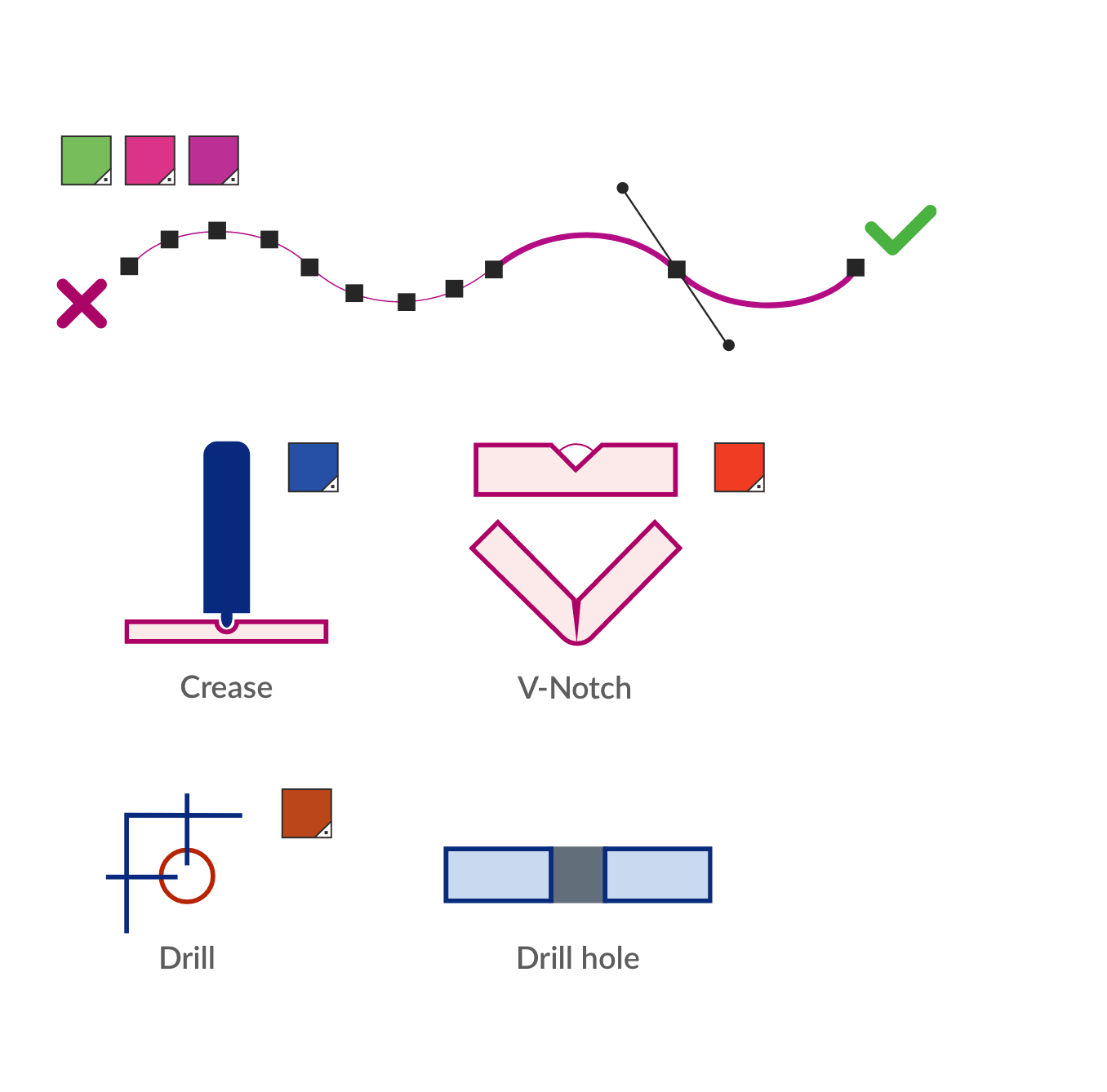

- Use simple, clean paths without unnecessary anchor points.

- Apply spot colours as strokes rather than fills, with a 0.25pt stroke weight

for optimal recognition. - Ensure closed paths for complete cutouts, unless intentionally creating an open cut.

- Position cut lines precisely where you want the cut to occur, remembering that the cut

will happen exactly on the path.

Creating fold and crease lines

For packaging elements using Crease or V-Notch spot colours:

- Use straight lines for best results.

- Apply a 0.25pt-0.5pt stroke weight to ensure visibility while maintaining precision.

- Verify fold directions to ensure the design folds as intended.

For elements using the Drill spot colour:

For packaging elements using Crease or V-Notch spot colours:

- Create small circles at drill locations.

- Centre circles precisely where you need the holes.

- Use consistent sizes for circles indicating the same drill bit size.

Working with white ink

When using the White spot colour:

- Consider the base material colour and how the white will appear against it.

- Use white as an underbase when printing coloured elements on dark materials.

- Create white knockouts where needed to maintain material transparency.

Checking your file before submission

Before submitting your file, verify that:

- All spot colours are correctly applied to the appropriate elements.

- No process colours are used where spot colours are required.

- All text is converted to outlines to prevent font issues.

- All spot colour stroke weights are appropriate (typically 0.25pt-0.5pt).

- The Separations Preview shows all expected spot colours as separate plates.

- Spot colour names remain unchanged from our original swatch library.

Common mistakes to avoid

- Mixing spot and process versions of similar colours

(e.g., using both CMYK black and Register Black). - Applying spot colours as fills for cut lines instead of strokes.

- Creating overly complex paths for cutting, which may cause production issues.

- Positioning cut lines too close together, which can cause material instability.

- Using incorrect spot colours for the intended production technique.

- Modifying spot colour names or values, which can cause confusion in production.

Troubleshooting spot colour issues

Spot colours don’t appear in the Separation Preview

- Check if the colour is actually a spot colour by examining the Swatches panel.

Spot colours have a small dot icon in the corner. - Verify that the colour hasn’t been converted to a process colour by right-clicking

the swatch and checking its properties.

Lines appear too thick or thin in the design

- Adjust stroke weights to the recommended 0.25pt-0.5pt for production lines.

- Ensure strokes are aligned to the centre of the path.

Unexpected results in production

- Use the Separations Preview to check each spot colour plate individually.

- Verify that overprinting settings are configured correctly for your design intent.